Double and triple glazing

Multiple glazing can greatly improve the energy efficiency of your home, while also enabling you to maximise window sizes to enjoy views and light.

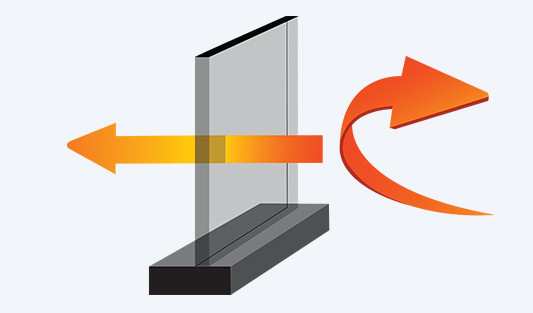

Single glazing was the standard for older homes, but it has poor insulating properties: heat and cold pass easily through it. Under the revised clause H1 of the New Zealand Building Code, double glazing is required on all new builds in order to meet national home energy-efficiency targets.

Types of window glazing

Make the most of double glazing

Colonial bars and lead lights

Thermal performance

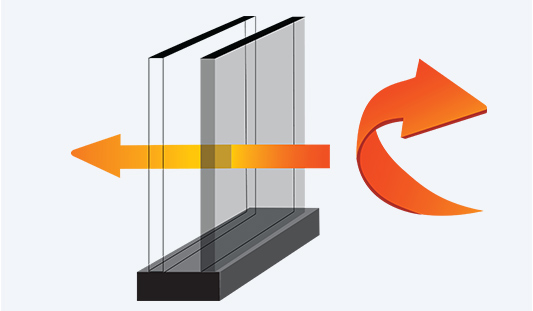

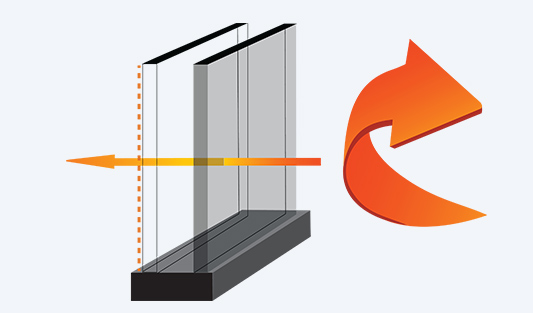

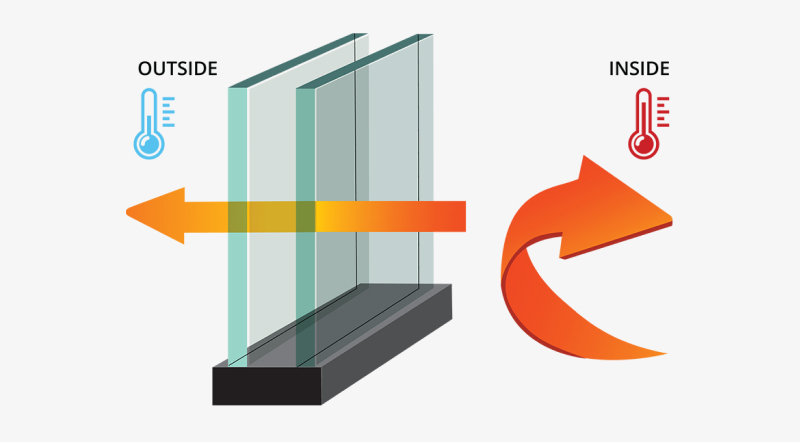

In an IGU, a layer of air is trapped in the sealed space between the two (or three) panes. The air acts as a thermal break, dramatically reducing the rate cold or heat can pass through.

Completing the IGU is the thermal spacer, a surrounding strip of material that is hermetically sealed to keep moisture out. Spacers are typically made of a metal such as aluminium or steel, or polymer foam. Each has its benefits in terms of its thermal performance and ability to expand and contract in changing conditions. Consult your professional installer for advice on your local situation. The thermal performance of an IGU is rated by its U value, and this can provide a useful guide to the difference multiple glazing could make in your home. The lower the U value, the more energy efficient the window is, meaning less heat is lost.

U-values and R-values

WEERS

Argon versus air

Life expectancy

IGUs typically carry a 10-year warranty and, as the purchaser, you will expect your glazing to last longer than the warranty period, but it will not last forever, even if well maintained. When, under normal use conditions, condensation (fogging) occurs within the space between the panes, the unit is deemed to have reached the end of its useful life.

With NZ’s diverse climatic conditions, during its life, your IGU is exposed to a range of environmental influences. These can include temperature and atmospheric pressure fluctuations, wind loads, sunlight / UV light, water, and water vapour, and in coastal locations salt-laden sea air. These environmental factors will influence the longevity of your IGU, and so will the design of the unit, its installation and how well it is maintained. We recommend you use units supplied by a member of the IGUMA (Insulated Glass Unit Manufacturers Association) and installed in accordance with industry guidelines.